DRIVE SYSTEMS

By engineers - for engineers

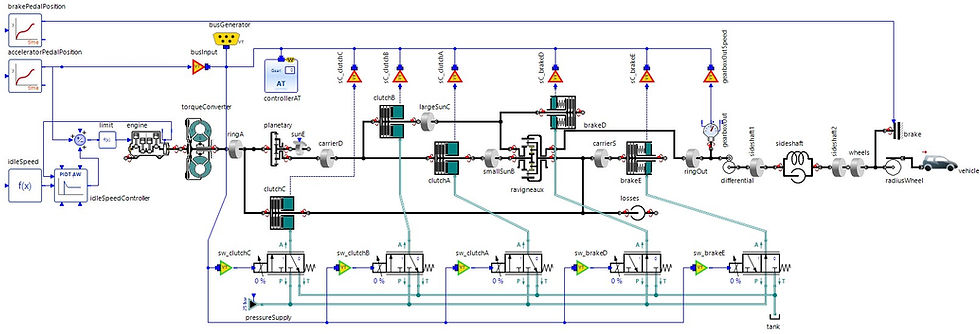

Simulation and modeling of drive systems for better performance and precision

Mechanical drive systems are at the heart of stationary and mobile machinery, machine tools, plants and vehicles. Engineers face intense requirements in terms of speed and precise positioning. With SimulationX for powertrain simulations, you are able to design powertrains for a wide range of machines quickly and reliably in a cost-efficient manner. Increase the efficiency of the entire driveline from the engine to the drive shafts, transmissions and the output.

Reliable and accurate determination of powertrain characteristics

For the analysis of a drive system’s behavior, frequency domain analyses provide a fast and viable method. Steady-state calculations are often required to prove operational safety as part of approval and certification procedures.

Drivetrain models in SimulationX can be simulated in both the time domain and frequency domain, helping to identify critical frequency ranges , and providing you with accurate and reliable results for any operational phases. Stress due to non-periodic excitation, such as ice impact on ship propulsion systems, can be simulated and quantified. Especially for safety-relevant drives, it is essential to know the exact behavior of the powertrain for normal operations, but also for malfunctions, emergency shutdowns and disastrous situations.

Powertrain simulation – Mastering speed and torque

In powertrains with combustion engines, torsional vibrations are usually caused by crank angle deviations. As a consequence of engine misfires or cylinder deactivation to save fuel, additional excitation may occur throughout the entire drive system. Backlash in the engine mount and in the transmission as well as strongly irregular loads, such as shocks, lead to abrupt changes in the effective torque and the rotational frequency.

Damping elements and elastic coupling add to this through their usually nonlinear behavior. In order to still be able to provide safe drive systems despite these complex vibrations and load scenarios, the individual components are often overdesigned. Powertrain simulation helps you ensure the functionality and operational safety of your machinery without the need to overdesign it.

This enables you to

-

optimize the dynamics and energy efficiency

-

reduce the design space for the drive system

-

and cut back on production costs.

Determine accurate waveforms and load curves in each component and examine the impact of vibration damping measures directly in the model.

Simulating drive systems, especially in terms of rotational speed and torque curves, helps you develop inexpensive and efficient drive systems and drive units with better dynamic characteristics. Drives that are subject to strong vibrations, which you can model through powertrain simulation, are found in many systems such as those at right.

Drive System Engineering for:

-

vehicles

-

ships

-

generators

-

wind turbines

-

construction equipment

-

shredders and chippers

-

crushers and belt conveyors

-

shakers and vibratory feeders

-

centrifuges

-

textile machinery

-

mining equipment

-

forestry equipment

-

industrial machinery

Efficient development of chain and belt drives with virtual models

Belt and chain drives transmit torque through translational movements from a drive to one or more output shafts. They are used in vehicles, agricultural and construction machinery, tools and processing machinery, but also in home appliances, such as washing machines and lawn mowers. Chains and belts transmit rotational movements and the induced torque fluctuations from one shaft to another. In contrast to gears and shafts, chains and belts cannot transmit compressive force.

Modeling belt drives

Sudden deceleration can cause the belt to lose tension or jump off the drive pulley. If the torque at the drive pulley increases abruptly, the torque can potentially no longer be transmitted through traction: the belt begins to slip. With the help of simulation software, you can quickly and reliably analyze vibrations occurring in the belt, determine whether the belt meets its desired functionality and examine its influence on the transmission behavior of the entire powertrain. The obtained data helps you answer a wide range of questions including:

-

What impact does the belt drive have on the powertrain’s overall behavior?

-

Can the belt transmit the desired torque?

-

How does the belt react to torque fluctuations?

-

How does the belt behave during emergency situations and shutdowns?

-

Is there any risk of the belt losing tension or jumping off the drive pulley?

-

What loads and strand forces occur within the belt?

-

Is there any risk of the belt to snap?

-

What lifespan can I expect for the belt based on the occurring loads?

Efficient development and testing of controlled drive systems

For best results, it is vital that controllers and mechanical parts work seamlessly together to achieve a stable system and the required performance.

Using control engineering for active vibration damping compared to passive damping has the advantage of minimized energy losses throughout the entire drive system. Traction control systems for vehicles and belt conveyors closely combine control engineering and drive technology. By analyzing different concepts through simulation models, you are able to test control strategies for optimized, controlled drive systems very efficiently and conveniently. Moreover, you can also quickly and easily test the interactions between your control units and machinery for different load cases and product configurations.

Optimized operating strategies for hybrid drives

In hybrid-electric powertrains, it is not only the mechanical behavior but also the optimal operating strategy that is of interest. In addition, there are questions about the necessary properties of the energy storage and energy supply:

-

What configuration of combustion engine and electric motor best fits the given operating profile?

-

How big should the energy storage be? -

How much energy must be provided within what time frame from the battery or from an external source? -

What is the best strategy for charging and discharging the batteries or the best operation strategy to combine the electric motor and combustion engine?

System simulation for hybrid drive systems helps you find the answers to these questions. Test a great number of different configurations and load cases in no time. Determine the best layout of your system components and find the most economical operating strategy for your hybrid drive.